For the hardware design of the car controller, the power supply system is a very important part.This article mainly introduces the power supply of sensors, microcontrollers, actuators, and communication.

1.Sensor power supply

Automotive controllers use a variety of sensors,These sensors usually require a stable and reliable power supply to ensure that they can function properly.The type of supply voltage depends on the type and design of the sensor, here are some common automotive sensor supply voltage types:

A. 5V: This is the most commonly used voltage in automotive electrical systems.Many sensors, such as temperature sensors, pressure sensors, and position sensors, require a 5V power supply.

B. 12V:12V is the standard voltage in automotive electrical systems, so many sensors, such as speed sensors, require a 12V power supply.

C. Other Voltage:In some large commercial vehicles or special application scenarios, it may be necessary to use 24V power supply.For example, some heavy trucks and excavators may need to use 24V power supply, etc.

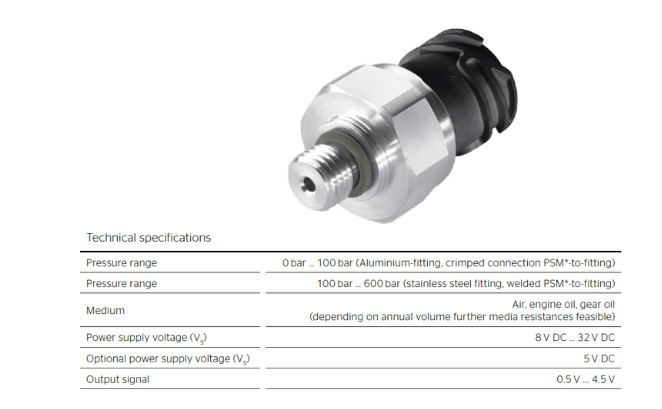

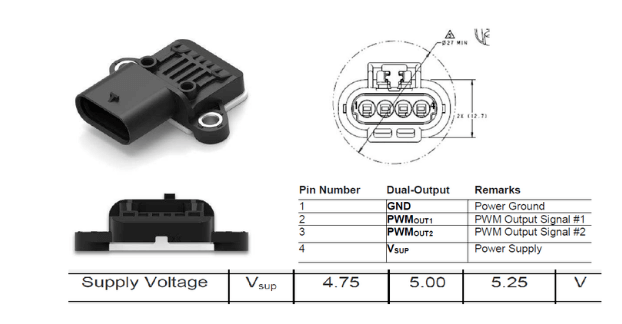

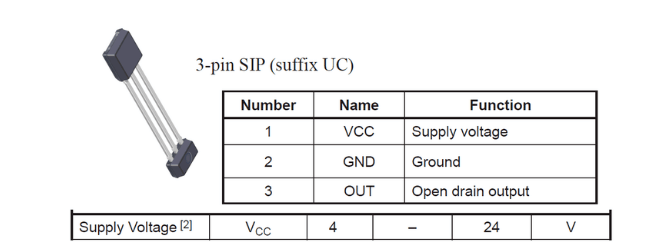

The supply voltage ranges of several sensors are listed below:

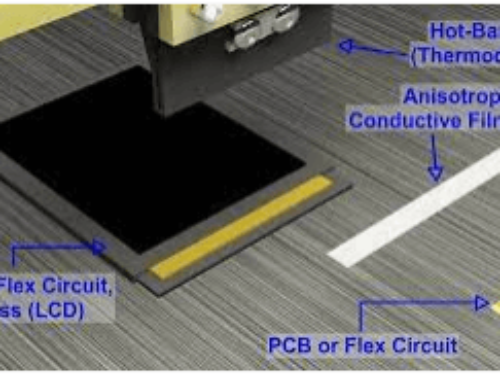

1)Pressure sensor, power supply voltage range 8V-32V, optional 5V.

2)Position sensor, power supply voltage range 4.75V-5.25V, typical value is 5V.

3)The speed sensor, the power supply voltage range is 4V-24V, generally 12V.

2. Microcontroller power supply

The supply voltage of the microcontroller can be divided into the following categories:

1)5V :5V is the most common supply voltage for microcontrollers, including many traditional 8-bit microcontrollers and some older 16-bit microcontrollers

2)3.3V: 3.3V is the more common supply voltage in modern microcontrollers, including many 32-bit microcontrollers and some newer 16-bit microcontrollers.Some small devices, such as portable devices, also often use 3.3V microcontrollers due to lower power consumption.

3)1.3V: Some newer microcontrollers, especially for low power consumption and high performance, require lower supply voltages.1.3V is a common voltage for some microcontrollers of this type.

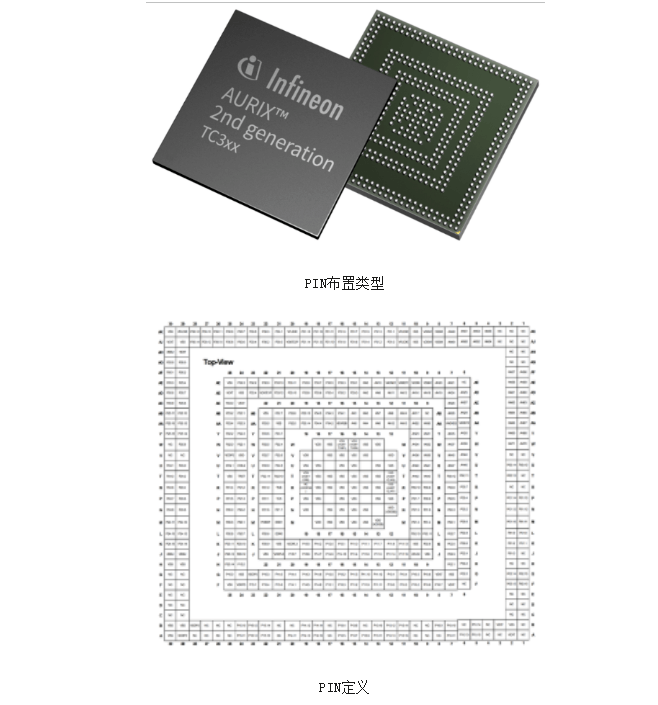

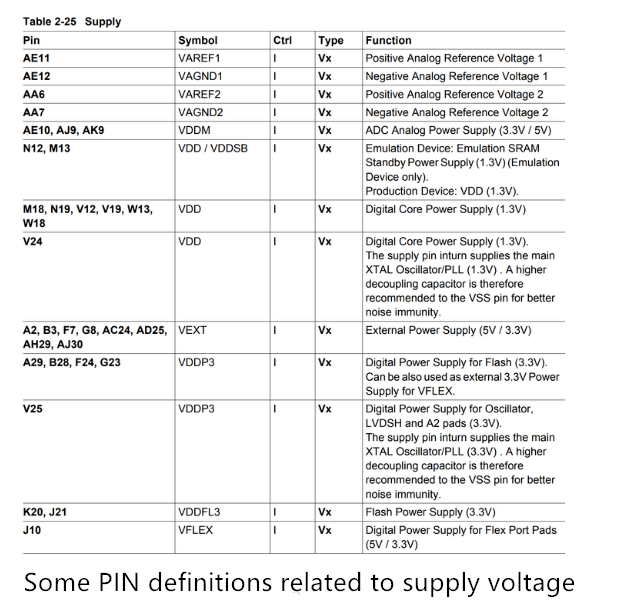

It should be noted that different microcontrollers may have different power supply voltage requirements, and the specific power supply voltage needs to be determined according to specific specifications. The following lists several power supply voltage values of Infineon Aurix TC3XX series.

It can be seen from the above that the TC3X microcontroller has three power supply voltages of 1.3V, 3.3V and 5V. .Usually, in order to ensure the stable operation of the microcontroller, it is necessary to provide a stable power supply for the microcontroller, which is usually ensured by using a dedicated power management chip and hardware processing circuit.

3.Actuator power supply

The car controller controls the actuator through control signals and electric energy conversion, etc., to realize the control and adjustment of various systems of the car.These actuator types mainly include the following:

1)motor actuator:Used to control the running state of automotive motors, such as BLDC, PMSM, IM, etc.

2)Solenoid valve actuator:It is used to control the operating status of the automobile hydraulic system and pneumatic system, such as brake valves, shift valves, etc.

3)Electromagnetic Relay Actuator:Circuits and electrical equipment used to control automobiles, such as electrical relays, electromagnetic contactors, etc.

4)Pneumatic actuators:Used to control the pneumatic and hydraulic systems of automobiles, such as brake pumps, air bags, etc.

5)Solenoid Actuator:Used to control operations such as locking and unlocking of the car, such as door locks, engine starters, etc.

6)Photoelectric switch actuator:Used to control photoelectric switches and proximity switches of automobiles, such as car light switches, wiper switches, etc.

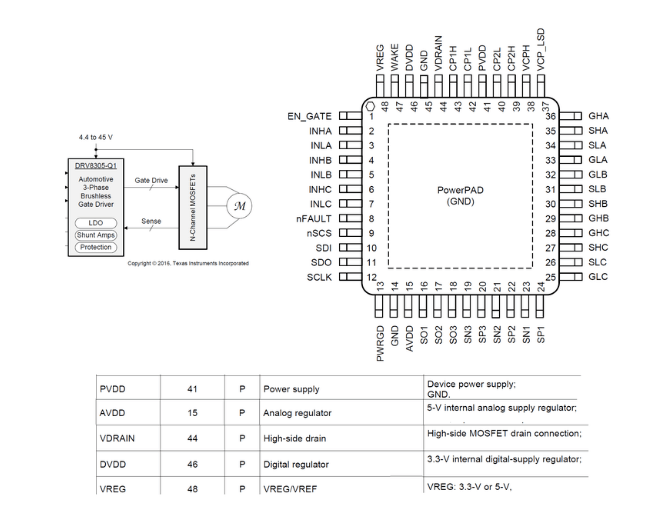

These actuators usually need to be driven by the peripheral chips of the microcontroller. The following is the BLDC driver chip. In order to ensure the normal operation of the chip, two power supply voltages, 3.3V and 5V, need to be provided.

4.Communication power supply

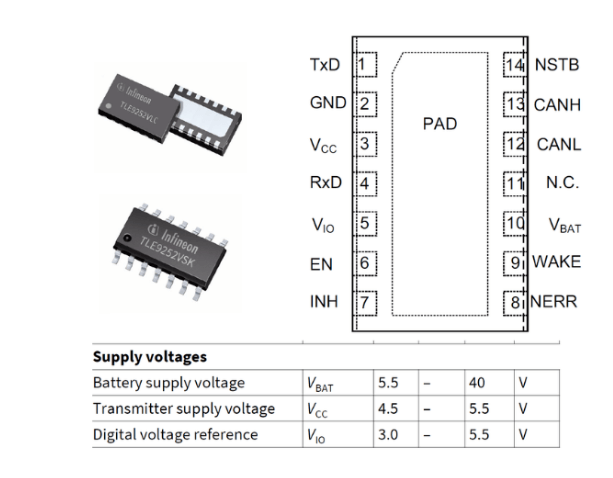

Communication is usually required between automotive controllers to exchange information,Taking CAN communication as an example, a CAN transceiver is required to convert the differential signal of the CAN bus into a logic level signal, so it is necessary to supply power to the CAN transceiver, as shown below:

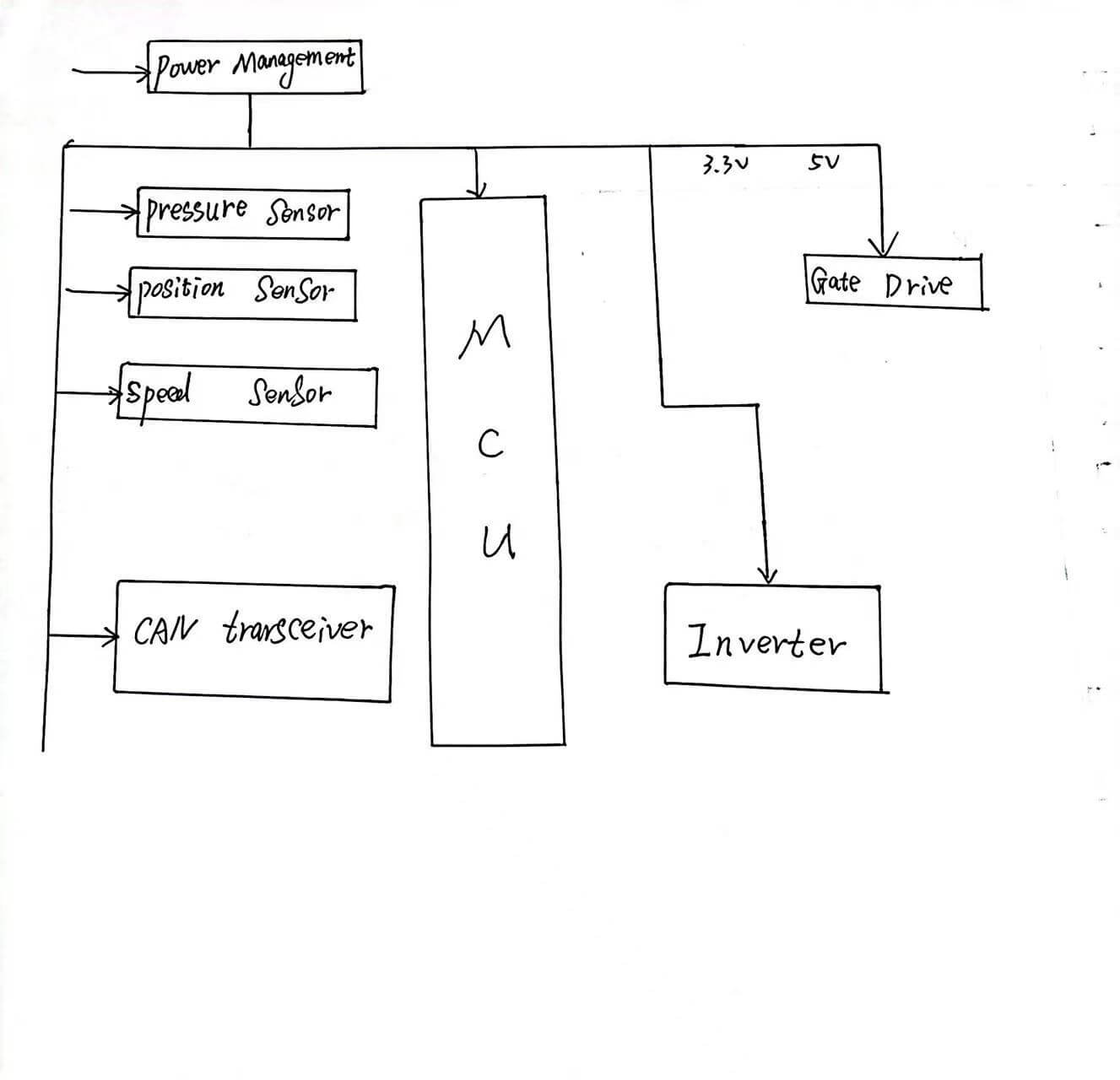

5.power supply system

In order to supply power to the above-mentioned electronic devices, the car controller needs a power supply management system, that is, a power management system, as follows:

The above is a basic introduction of the power management system of the car controller,To sum it up is:

.Microcontroller:The microcontroller in the automotive controller is the heart of the entire system and needs to provide a stable and reliable power supply.Typically, the supply voltages for microcontrollers are 1.3V, 3.3V and 5V, which need to be provided through the power management system.

.Sensor:There are many types of sensors in automotive controllers, such as temperature sensors, pressure sensors, position sensors, and speed sensors, etc. The supply voltage range for these sensors is usually 3V to 5V or a little higher 12V, which needs to be provided by the power management system.

.Actuator:There are many types of actuators in automotive controllers, such as motor actuators, solenoid valve actuators, steering gear actuators, etc. The supply voltage range of these actuators is usually between 3V to 5V or 12V to 24V, which needs to be provided through the power management system.

.Communication chip:Communication chips in automotive controllers include CAN bus controllers, LIN bus controllers, etc. The power supply voltage of these communication chips is usually between 3.3V and 5V, which needs to be provided by the power management system.

.Memory:Memories in automotive controllers include flash memory, RAM, etc. The supply voltage of these memories is usually between 1.8V and 3.3V, which needs to be provided by the power management system.

.Other auxiliary equipment:There are some other auxiliary equipment in the car controller, such as buzzer, electronic horn, etc.The power supply voltage range of these devices is different, and it is necessary to select a suitable power management solution according to the specific situation.