PCB Basic Knowledge

PCB (Printed circuit board) which appears in most of electronic device. If there are some electronic components in the device, they must be embed in different size of PCB. In addition to fix different of small parts, the main function of PCB is to let all components on it are electrically connected to each other. With the electronic devices become more complex and require more and more parts, the lines and components on PCB are more and more intensive.

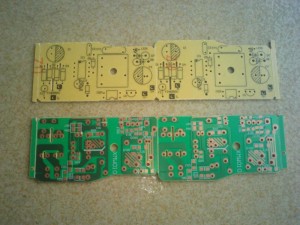

The substrate of Printed Circuit Board are made by insulated material which are no easy to bend, You can see the small line which made by copper foil on the surface of PCB, the copper foil should be covering the entire board, but some of the cooper foil are etching during the manufacturing process, the rest are become those mesh lines . These lines are called conductors (conductor pattern) or said wiring, and used to connect all the components on the PCB.

In order to fixed all components on the PCB, we need weld their feet directly on the wiring. Like the most basic PCB (single-sided), the parts are concentrated on one side, wire were concentrated on the other side. Then we need drilling a hole on the board to let weld pin to get through to the other side of the board, and all components are welded pin on this side. So the front and back of PCB are called Component Side and Solder Side.

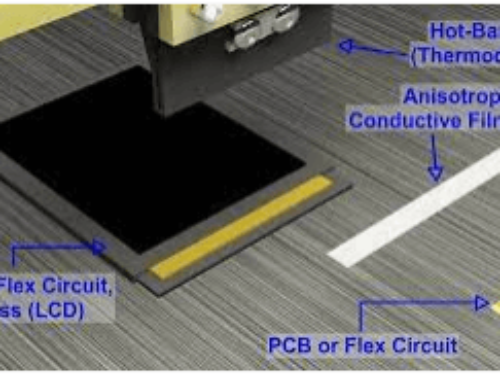

If you want to link two pieces PCB, usually we need to use the edge connectors which called ”gold finger” ,The Gold finger contains many bare copper pad which is also a part of a PCB wiring. When connection, we let the gold finger on the PCB inserted into the appropriate slot on another onePCB (also called expansion Slot). Like the computer, such as video card, sound card or other similar interface cards, are connected through the gold finger to the motherboard.

Green or Blue or Red(color can according to the customers’ requirement) on the PCB are the solder mask color. This layer is an insulating protective layer which can protect the copper wire and prevented the components welded to the wrong place. There usually would have a silk screen on the Solder Mask, it will be printed the text and symbols (mostly white) to mark the position of the components on the board. Silk Screen also called legend.